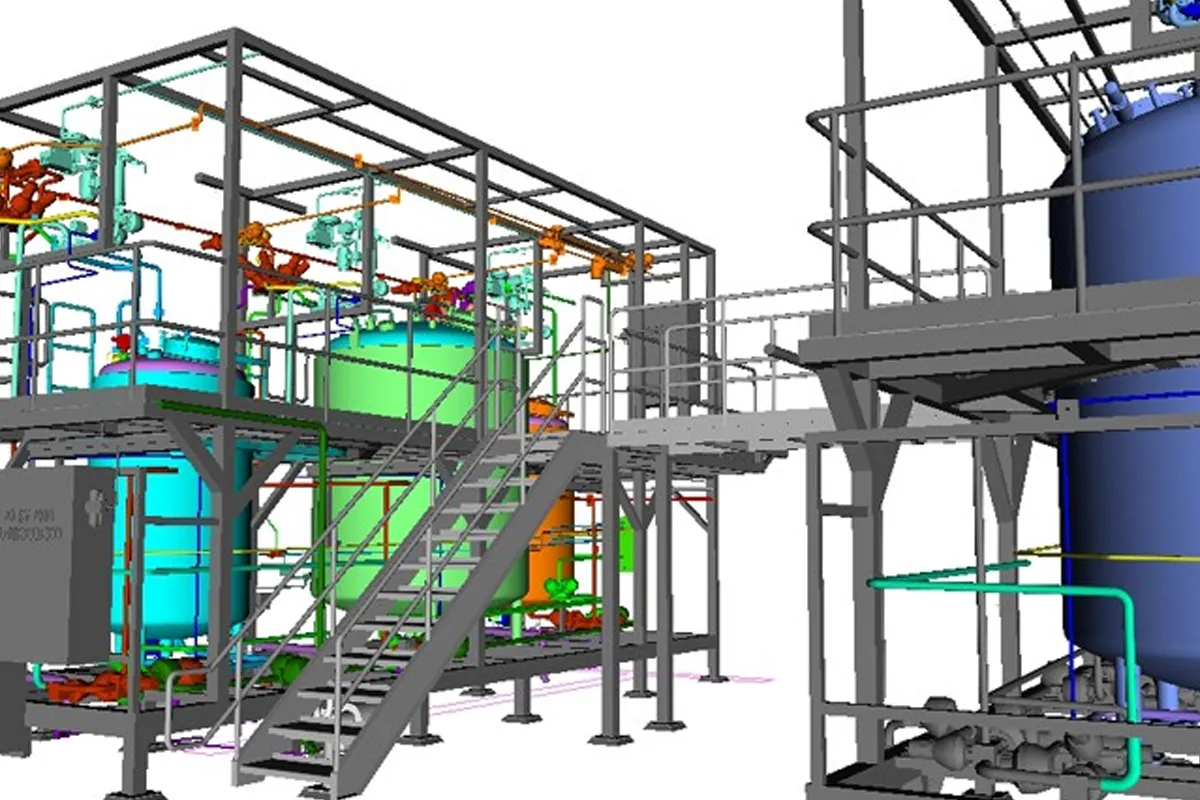

Design & Engineering

Our engineering staff averages over 10 years in tenure at Holland. We have experience in pharmaceutical system projects ranging from small pump carts to large multi-million dollar sanitary modules. Our engineering staff has created designs for managed the construction of literally hundreds of sanitary process skids and modules.

Design Capabilities

Turnover Packages

We build paper and electronic copies of the turnover package simultaneously. Normally completed TOP’s ship with the skids, not weeks or months after shipment. Turnover packages are organized in such a way as to make review at FAT fast and easy.

Our design stack includes AutoCAD (with Cadworx add-on) and Navisworks rendering software.

Manufacturing

Since 1903, Holland Applied Technologies has offered an array of world-class manufacturing services to the biotech, pharmaceutical, food & beverage, personal care products, and other high purity markets.

FAT Utilities Available

Welding

- Computer controlled orbital welders with weld documentation capabilities

- Jet drive welding stations

- Dedicated argon dewers with certs

- Oxygen control system to monitor purge gasses on each orbital welder

- All welders are certified to ASME Section IX requirements

Machining

- Hitachi Seiki machining center

- CNC vertical milling center

- Milling machines

- Engine lathes

Polishing

- Assorted ID and OD mechanical polishing equipment

- Most polishing is done in a isolated room with its own air purification system

- Electropolishing is available

What Our Customers Have to Say…

“Holland will put in the time and effort up front to fully comprehend complex processes, resulting in a system that meets, and frequently surpasses, expectations.”

Process Engineer – Pharmaceutical Contract Manufacturer

“Holland has been a reliable partner for many years. They have the ability to support our business thru their vast inventory of repair components, onsite field service and new replacement components. Holland has been proactive in providing recommendations for repair kits as well as carrying safety stock at their facility to support our specific needs.”

Operations Manager – Food Processing Facility

“Holland understands our need for not only quality products, but the detailed documentation and material traceability required in the pharmaceutical industry. We’ve used their Document Locator tool to help manage documentation for our production equipment. It’s been great to have a historical record of documentation covering our long-term relationship.”

Quality Manager – OEM of Single Use Biotech Equipment

““Holland Applied is a business partner that I find to be highly trustworthy, competent, and customer focused. We keep using them for our machining and fabrication needs because we know we can rely on them to provide high-quality goods on time and at competitive market prices.”

Head of Procurement – Injectable Drug Manufacturer